Your Industrial Heat Exchanger Solution

Why Lepido?

In challenging ventilation environments – just look at the pictures below - you need a heavy-duty solution to handle all that soot and grease. Lepido, designed to operate robustly in polluted air streams, can be deployed in a wide range of different process ventilation systems. The pollutants may vary, and – to name a few examples – range from grease and soot in restaurant ventilation, to wax and lint in industrial laundries, to residual lacquer and sawdust in woodworking industries and back to grease and water vapour in food processing and snacks production.

Particle Repellent Geometry

How PRG works

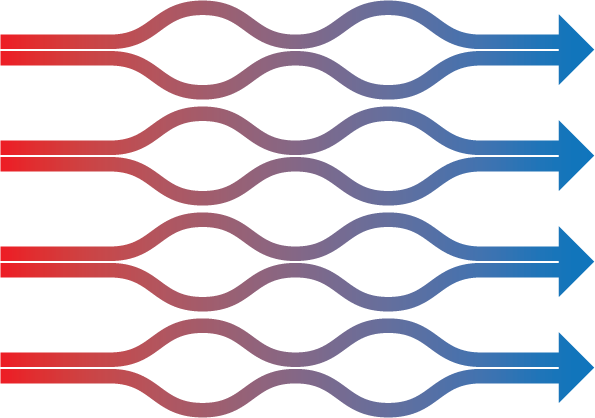

Lepido, being a heavy-duty heat exchanger, is larger compared to a traditional heat exchanger to make room for our patented geometry of the recovery coils. The space between the coils is much larger than between fins of a traditional heat exchanger.

The result is a unique airflow pattern where most of the particles can pass through the heat exchanger instead of sticking to the coils. This slows down the build-up on the coils and makes the air pressure drop minimal, even if a coating has formed.

Lepido, being coil-based with one hundred percent counter-current and multiple fluid patterns, has the same heat transmission element surface area as a traditional heat exchanger.

Particle Repellent Geometry

Areas of usage

With our innovative PRG approach, the majority of particles breeze through the heat exchanger effortlessly, avoiding any obstructions.

The applications of Lepido includes but is not limited to:

- Restaurants

- Fast-food establishments

- Laundries

- Food processing facilities

- Woodworking workshops

- Chemical industries

- Food courts

- Join us in revolutionizing and reusing waste heat across diverse industries