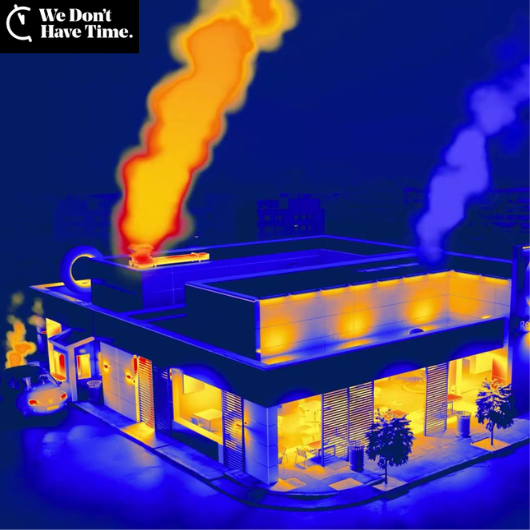

The global demand for energy is booming — it’s set to bump up nearly 30 percent by 2040. Some say that recapturing excess heat could power most of Europe.

And while much is being done, engineers have struggled to resolve heat capture in some of our most punishing environments. Commercial kitchens and laundries, heavy industry sites and others are pumping hot, greasy, polluted air into the atmosphere. What a waste. Most experts have thought it impossible to extract clean heat energy from these polluted airstreams. And they were right. Until now. Finally, polluted heat exhaust can be recycled into heat energy. We’re turning waste into watts.

Enjay is a Swedish Greentech company specialized in energy efficiency in hostile environments. We have developed a technical platform that is able to recover energy in polluted airstreams where existing technologies are unable to operate.

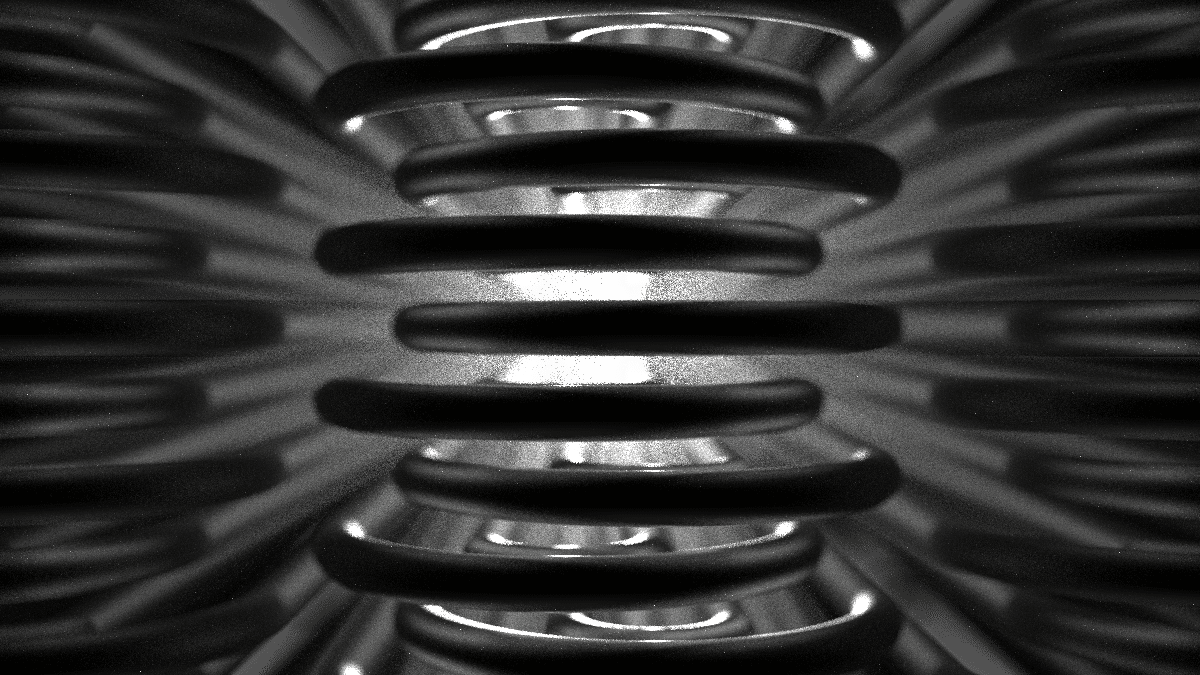

Enjay’s first innovation, Lepido, is a heavy-duty heat exchanger for polluted exhaust air. It makes energy recovery in impossible environments not only possible but also profitable.

“We have created a financial incentive for our customers to reduce their climate impact. Wasting energy is no longer an option”

We’re on a journey to reduce the global CO2 emissions by 500 megatons annually – one percent of the estimated global emissions by 2050.

Why there is serious money in kitchen fumes

On the windy roof of a Burger King in Malmö, southern Sweden, Maggad Khalidy points to a large metal box attached to a jungle of pipes and wires. From the outside, it's far from an eye-catching innovation, but Mr Khalidy, who owns the fast food franchise that runs this restaurant, says it has saved the branch the equivalent of around $16,000 (£13,000) a year in heating bills.

Enjay drives kitchen costs down at Burger King and Turtle Bay

How we turned a massive failure into a climate solution that could cut global emissions by 500 megatons

It might sound too good to be true, but it’s not. The solution is called Lepido, and it is now being deployed by big food chains, industrial production sites, and small restaurants in several countries.